Making a SLG2006C Burner Bracket

Burner brackets are usually bolted to the back of the grill and hold up the back of the burners. They are in many, but not all, of the bigger stainless steel grills. They usually have a few crossover tubes to help light the burners. In this case, the customers were looking for the bracket. I didn't have it. But I was able to make some pieces in return for the old one. I duplicated the parts locally and placed them in our inventory. I had some old sheet metal equipment that I used to make these parts.

Img 2637 - Here I am out in the shop, with the wrong part and a drawing with measurements that the customer sent me. That’s a 4 foot stomp shear I used to cut the pieces I needed to make this thing.

Img 2638 - I have gathered some stainless sheet metal pieces and start here. You step on the long pedal below the work surface.

Img 2639 - I have a sheet laid out on it to cut the basic pieces.

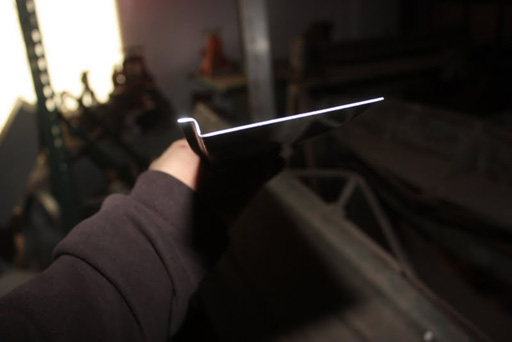

Img 2640 - That’s a strip for the bracket that I'll "break" (bend) in the metal brake.Img 2641 - I've cut the pieces and am breaking them here.

Img 2642 - There's the first bend in the long bracket.

Img 2643 - Made the second here.

Img 2644 - One more bend.

Img 2645 - I've got the bracket made which is like the one I sold him but the crossovers are different.

Img 2647 - I've cut out the pieces for the crossovers and have to bend them.

Img 2651 - I think I needed 4 of them but I made an extra one.

Img 2652 - I can't make the all the bends/breaks and I use some channel locks to finish.

Img 2653 - Now, to attach the crossovers I have to drill and then rivet them together.

Img 2654 - Here I am using the rivet tool to attach them.

Img 2655 - The one I made in front still needs to have the holes drilled.

Img 2656 - Definitely the one on the right is not yet finished. When I get an original, which is often all rusted, I'll take it to a local fabricator for duplication. We have a line of parts, all noted by our CLA as part of the part number, made in the USA.

Img 2659 - This photo shows the wrong one, which I had sent him (and which was made by the local fabricator) next to the one I made. The customer sent me his old one.