Coleman 3000

CARL'S GRILL HELP - COLEMAN

I borrowed this Coleman 3000 from a local customer. It uses our 15902/SBT21 burner which is a copy of of the factory burner. Some of our customers have had a problem getting our burner to fit properly, often failing to connect the venturi openings to the orifices. They have claimed the venturi are as much as 1/2 inch short of connecting. I have worked on a few of these grills (some Sunbeams as well) that use the 15902/SBT21 burners (OEM part number 10030-5611-Coleman).

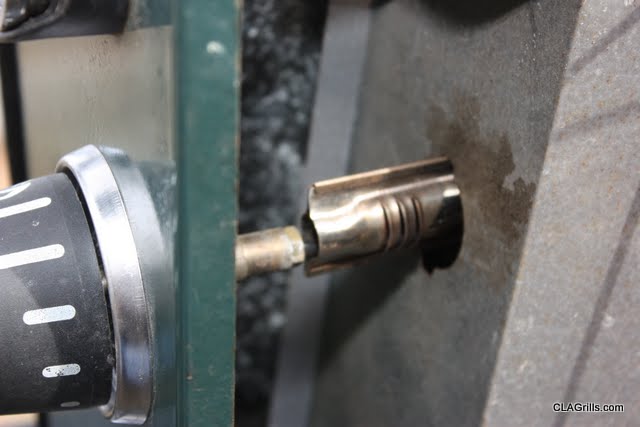

The warming rack, cooking grids and top heat diffuser, come right out. I needed a Hexhead wrench to remove the screws holding the ends of the heat tent. This one had stainless steel screws and came right out. The burner is right below that and requires the cotter pins on the side to be removed as well as the two wires outlets connecting to the electrods underneath the grill. With that, I had to pull the burner up slightly from inside the grill so that the electrods clear the grill bottom and then pull the burner out. This grill has a flame shield that slides over the venturi between the valve and the venturi under the grill casting, behind the control panel. I had to get on one knee with one hand under the control panel and the other pulling the burner out.

Before I pulled the burner out I looked at the venturi orifice connection. I found that they were barely connected. The orifice was just inside the venturi opening by less than 1/16 inch. Since our burner is a duplicate of the original I knew that the factory intended for more of the venturi to be over the orifice. I did notice that the control panel was bowed out slightly. I could easily push it in from the edge under the knobs to make up the difference, almost 3/4 inch. I had to push the edge in to straighten it or even bow the control panel edge into the grill slightly to overcome the difference. You could drill a hole in the control panel under the valve at the edge and on the back bracket and use a length of wire to pull the edges together, reducing the bow in the control panel. This would allow the burner venturi to be closer to the 1/2 inch it should have over the orifice end.

I am certain the factory did not intend to have this problem but the control panel edge is not strong enough to keep from bowing and it will probably bow out which causes the valve assembly to pull away from the burner venturi end. The burner can only be installed in one place and cannot be pulled forward to accomodate the difference. You may have to push the lower control panel edge forward to make up the difference and restore the valve-burner venturi postion to its original place.

Our burner assemblies,15902 and SBT21 are copies of the factory burner. The only difference is that ours is 100% stainless steel and the factory burner has a stainless burner with alumized venturi.